Products

Contact Us

Mobile: 86-139-5343-6993

Phone: 86-534-5541031

E-mail: info@bmixer.com

WhatsApp: 8613953436993

Add: North of the East End of Qianjie Street, Dacao Town, Ningjin County, Dezhou City, Shandong Province, China

It features a novel structure and has the advantages of high production efficiency, good stirring quality, light weight and beautiful appearance. It is a relatively advanced model. It is applicable to industries such as construction sites, bridge construction, pavement construction, high-speed railways, road construction, and water conservancy projects.

The vertical shaft planetary mixer is of high quality and high efficiency, ensuring uniform mixing without dead corners. It is widely used in industries such as building materials, concrete (dry-hard, semi-dry-hard, plastic concrete, UHPC ultra-high performance concrete, fiber concrete), refractory materials, chemical engineering, foundry, metallurgy, ceramics, and glass, solving the problem of mixing processes that require high homogeneity of materials.

It is equipped with multiple shaft end sealing protection devices and wind pressure sealing protection devices, effectively preventing the occurrence of slurry leakage. The unique mixer monitoring system can monitor the working status of the reducer, discharge pump and electric lubricating oil pump at any time. It is equipped with a DC 24V concrete mixer dedicated centralized lubricating oil pump. The operation time can be programmed independently. It is waterproof, dustproof and has excellent performance. The multi-pipe and multi-path water spraying system can evenly spray water. The whole machine is designed for heavy-duty use and operates stably. Equipped with an enhanced reducer, it has a strong load capacity, uses military materials, and is processed with high-precision technology, thus having a longer service life.

It is equipped with multiple shaft end sealing protection devices and wind pressure sealing protection devices, effectively preventing the occurrence of slurry leakage. The unique mixer monitoring system can monitor the working status of the reducer, discharge pump and electric lubricating oil pump at any time. It is equipped with a DC 24V concrete mixer dedicated centralized lubricating oil pump. The operation time can be programmed independently. It is waterproof, dustproof and has excellent performance. The multi-pipe and multi-path water spraying system can evenly spray water. The whole machine is designed for heavy-duty use and operates stably. Equipped with an enhanced reducer, it has a strong load capacity, uses military materials, and is processed with high-precision technology, thus having a longer service life.

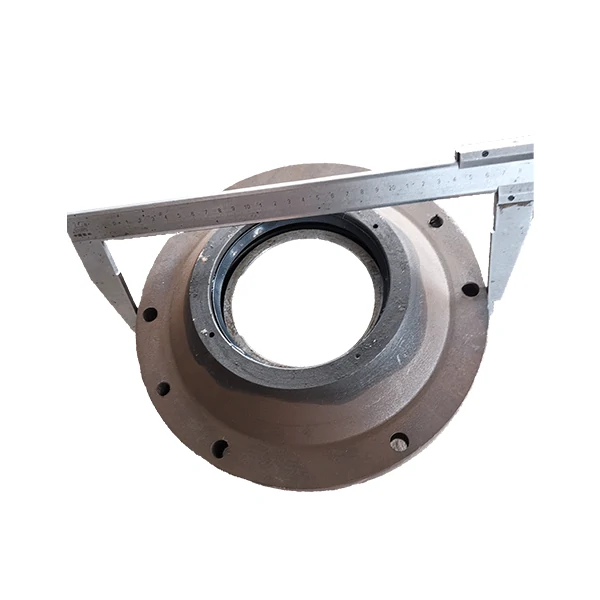

The shaft end sealing parts of Shandong Micos concrete mixer are cast with high-chromium alloy. The modular design increases maintenance efficiency by 50%. It is compatible with high-grade concrete of C50 and above, and is typically applied in high-speed railway Bridges and other projects.

The blades of the concrete mixer are made of high-chromium alloy cast iron and strengthened through special heat treatment. It is compatible with high-grade concrete above C50 and hydraulic concrete. Precisely manufactured through CNC machining centers, the homogeneity of the mixing has reached the leading level in the industry.

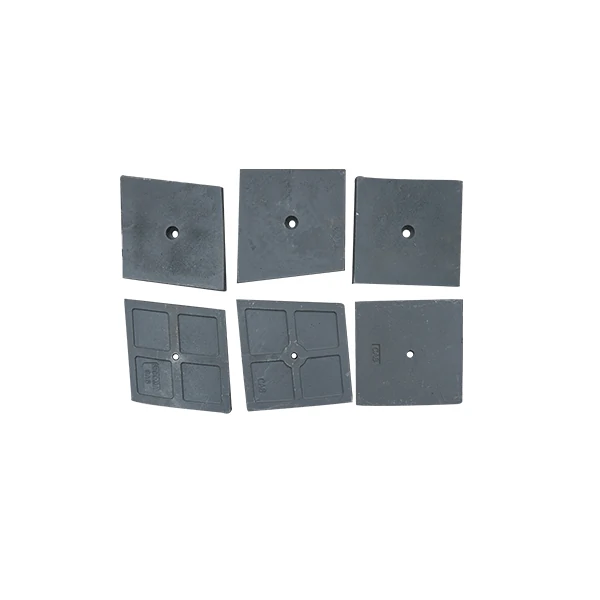

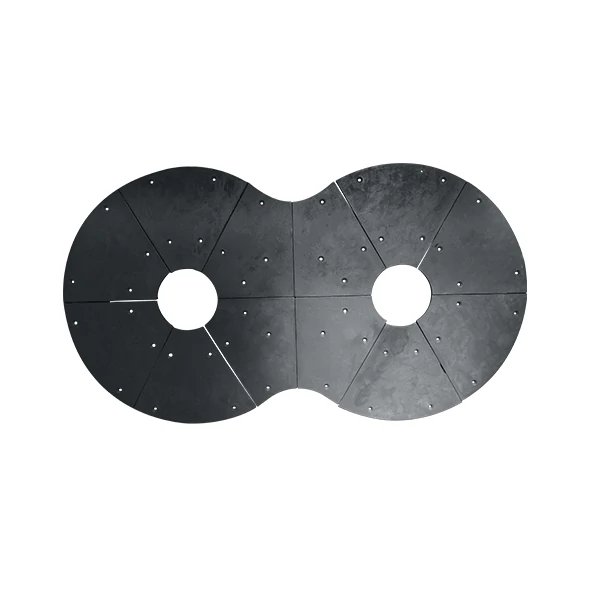

The lining plate of the concrete mixer is made of high-chromium alloy cast iron and strengthened through a special heat treatment process. The liner, blades and shaft body are designed with fluid optimization to reduce material collision wear.

The lining plate of the concrete mixer is made of high-chromium alloy cast iron and strengthened through a special heat treatment process. The liner, blades and shaft body are designed with fluid optimization to reduce material collision wear.

The concrete mixing arm is made of high-chromium alloy cast iron and its wear resistance is enhanced through heat treatment process. The split assembly structure makes it convenient to replace the wear-resistant sleeve. It is widely used in large-scale projects such as high-speed railways and Bridges, and is suitable for the mixing of dry-hard and plastic concrete.

The stirring arm enables seamless mixing and is suitable for high-performance concrete. It adopts high-strength wear-resistant materials and surface strengthening processes. The streamlined arm body reduces resistance. The parallelogram blades can be flipped 180° for reuse. The clamping block structure makes it convenient to replace the wear-resistant sleeve.

The blades of the concrete mixer are made of high-chromium wear-resistant cast iron and are strengthened through a special heat treatment process. It is suitable for dry-hard, plastic and high-grade concrete above C50, and the uniformity of mixing reaches the leading level in the industry.

The shaft end hub of the concrete mixer is made of high-alloy wear-resistant material and undergoes a special heat treatment process. The modular design supports quick disassembly and assembly, and is compatible with high-grade concrete above C50 and dry-hard concrete. It is typically applied in bridge, water conservancy and other projects.

The shaft end hub of the concrete mixer is made of high-alloy wear-resistant material and undergoes a special heat treatment process. The modular design supports quick disassembly and assembly, and is compatible with high-grade concrete above C50 and dry-hard concrete. It is typically applied in bridge, water conservancy and other projects.

The shaft end hub of the concrete mixer is made of high-alloy wear-resistant material and undergoes a special heat treatment process. The modular design supports quick disassembly and assembly, and is compatible with high-grade concrete above C50 and dry-hard concrete. It is typically applied in bridge, water conservancy and other projects.

The shaft end hub of the concrete mixer is made of high-alloy wear-resistant material and undergoes a special heat treatment process. The modular design supports quick disassembly and assembly, and is compatible with high-grade concrete above C50 and dry-hard concrete. It is typically applied in bridge, water conservancy and other projects.

The shaft end hub of the concrete mixer is made of high-alloy wear-resistant material and undergoes a special heat treatment process. The modular design supports quick disassembly and assembly, and is compatible with high-grade concrete above C50 and dry-hard concrete. It is typically applied in bridge, water conservancy and other projects.