Products

Contact Us

Mobile: 86-139-5343-6993

Phone: 86-534-5541031

E-mail: info@bmixer.com

WhatsApp: 8613953436993

Add: North of the East End of Qianjie Street, Dacao Town, Ningjin County, Dezhou City, Shandong Province, China

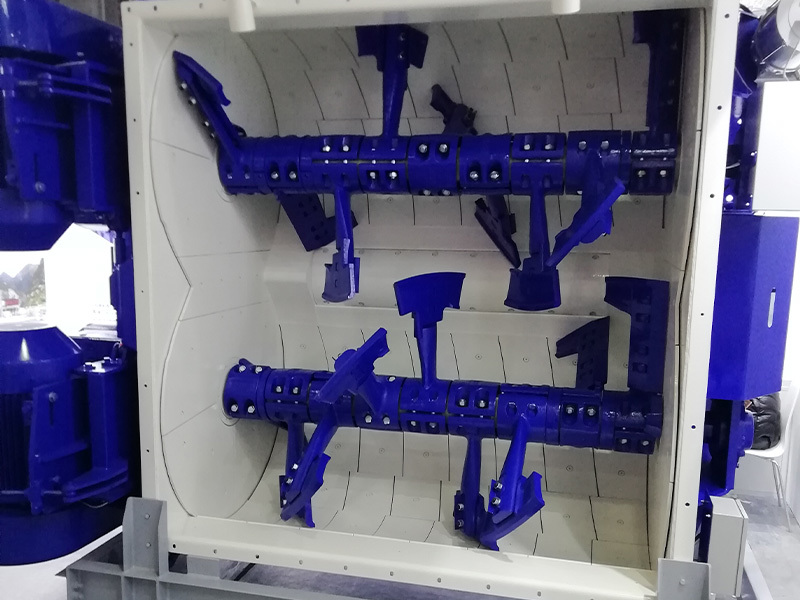

SDMIX brand JS1500

The concrete mixing arm is made of high-chromium alloy cast iron and its wear resistance is enhanced through heat treatment process. The split assembly structure makes it convenient to replace the wear-resistant sleeve. It is widely used in large-scale projects such as high-speed railways and Bridges, and is suitable for the mixing of dry-hard and plastic concrete.

Key words:

Detail

Parameter categories | JS1500 mixing arm | JS2000 mixing arm | JS3000 mixing arm |

Material composition | High-chromium cast iron | High-chromium cast iron | High-chromium cast iron |

Size specification | Main stirring arm: Length 850mm × Width 120mm × Thicknes 35mm | Main stirring arm:Length 1200mm × Width 180mm × Thicknes 45mm | Main stirring arm:Length 1500mm × Width 200mm × Thicknes 50mm |

Installation parameters | Bolt | Bolt | Bolt |

Dynamic parameters | Stirring shaft speed 25.5r/min | Stirring shaft speed 23r/min | Stirring shaft speed 28r/min |

Life expectancy performance | 80,000 to 120,000 cans | 120,000 to 180,000 cans | 150,000 to 200,000 cans per session |

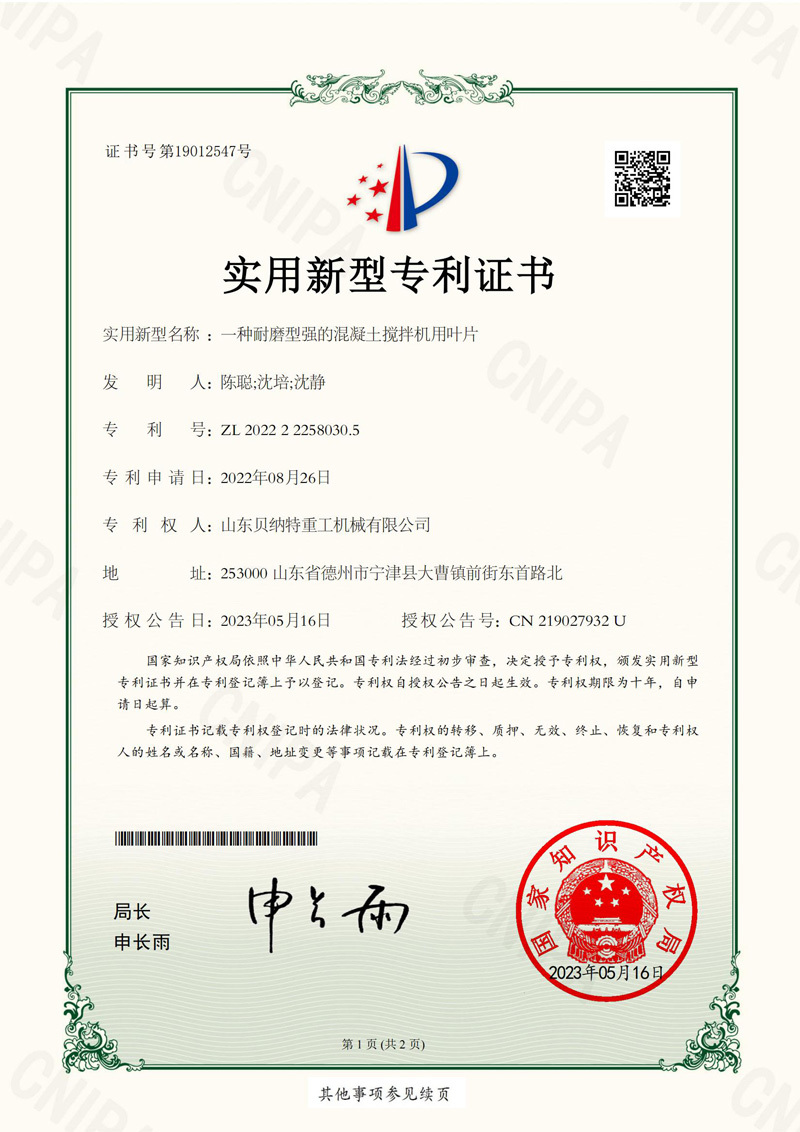

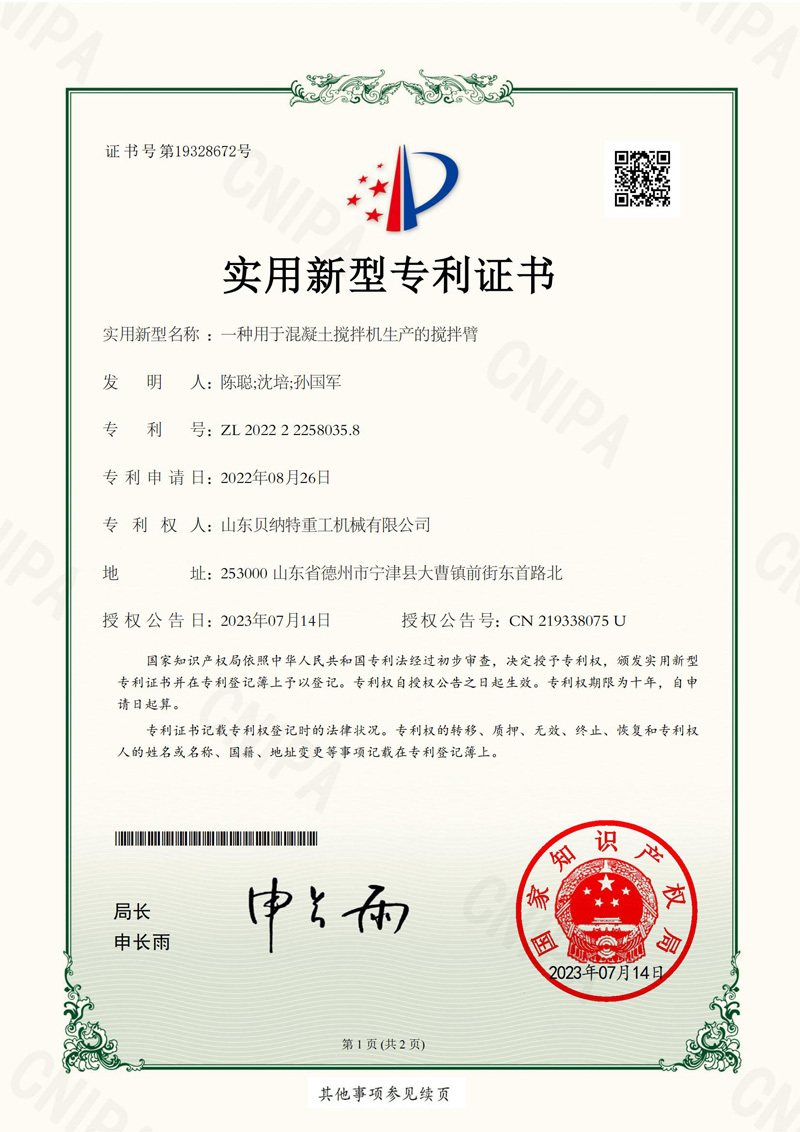

Quality Inspection Certificate

Casting production equipment

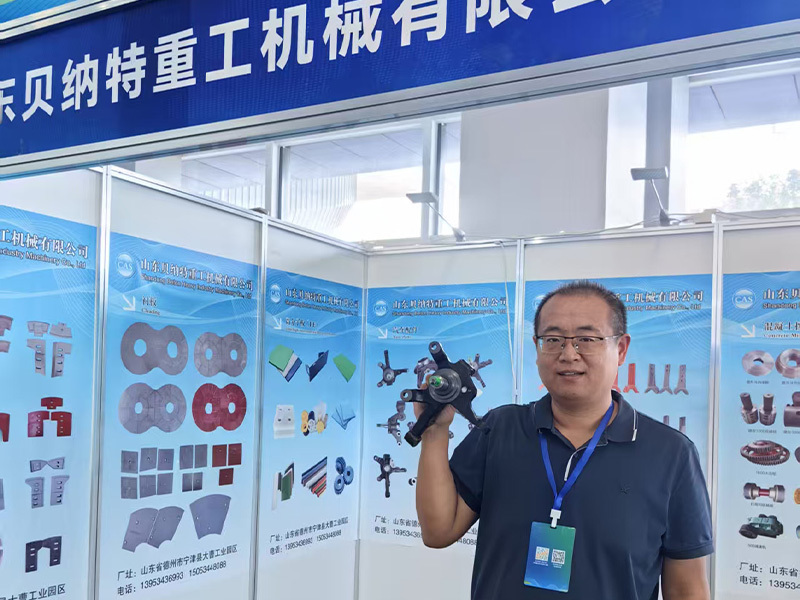

Exhibition

Inquiry

Please fill in the contact information and your needs, we will arrange professionals to contact you!

FAQ

Q

What types of mixer accessories does your company mainly produce?

A

We focus on producing the core wear-resistant parts of the JS series forced concrete mixers, including:

Mixing arm (double spiral belt/spiral blade type)

High chromium alloy liner (bottom plate/side plate)

Hydraulic seal shaft end assembly (including floating oil seal)

Wear-resistant alloy blades (spiral angle can be customized)

Wear-resistant guard plate for mixing tank

Q

How to ensure the wear resistance of the accessory material?

A

Triple strengthening process is adopted:

① Material upgrade: Liner/blade uses Cr20Mo2 high chromium alloy with a hardness of HRC58-62; shaft end uses QT600 ductile iron

② Structural optimization: The hyperbolic design of the mixing arm reduces material impact loss

③ Process guarantee: EPC lost foam casting

Q

How to confirm that the accessories match my equipment model?

A

Please provide any of the following information, and we will provide free adaptation verification:

✓ Host brand and model (such as: Sany JS2000, Zoomlion JS3000)

✓ Original accessories part number

✓ Measurement of key dimensions

Q

Is there any non-standard customization service?

A

We support personalized needs.