Products

Contact Us

Mobile: 86-139-5343-6993

Phone: 86-534-5541031

E-mail: info@bmixer.com

WhatsApp: 8613953436993

Add: North of the East End of Qianjie Street, Dacao Town, Ningjin County, Dezhou City, Shandong Province, China

Conele brand JS1000

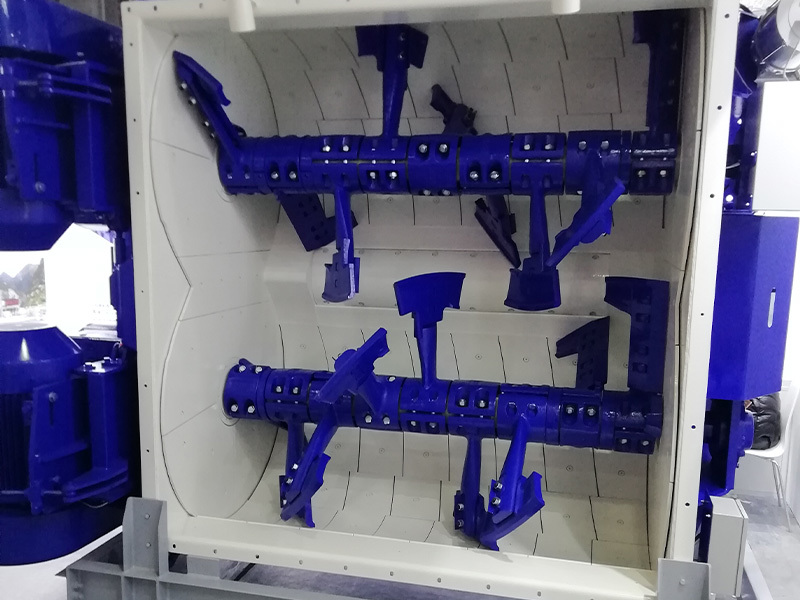

The stirring arm enables seamless mixing and is suitable for high-performance concrete. It adopts high-strength wear-resistant materials and surface strengthening processes. The streamlined arm body reduces resistance. The parallelogram blades can be flipped 180° for reuse. The clamping block structure makes it convenient to replace the wear-resistant sleeve.

Key words:

Detail

Parameter category | JS1000 mixing arm | JS2000 mixing arm |

Material composition | High-chromium alloy cast iron | High-chromium alloy cast iron |

Size specification | Main stirring arm: Length 850mm× Width 120mm× Thickness 35mm | Main stirring arm: Length 1050mm× Width 150mm× Thickness 40mm |

Installation parameters | High-strength bolt fixation | High-strength bolt fixation |

Life expectancy performance | The standard working condition life is 80,000 to 120,000 tank cycles, while in the quartz sand aggregate scenario, it drops to 40,000 to 60,000 tank cycles | The standard working condition life is 60,000 to 100,000 tank cycles, while in the quartz sand aggregate scenario, it drops to 30,000 to 50,000 tank cycles |

Maintenance cycle | Check the wear amount every 5,000 tanks. When the remaining arm thickness is ≤15mm, replacement is required | Check the wear amount every 3,000 tanks. When the remaining arm thickness is ≤18mm, it needs to be replaced |

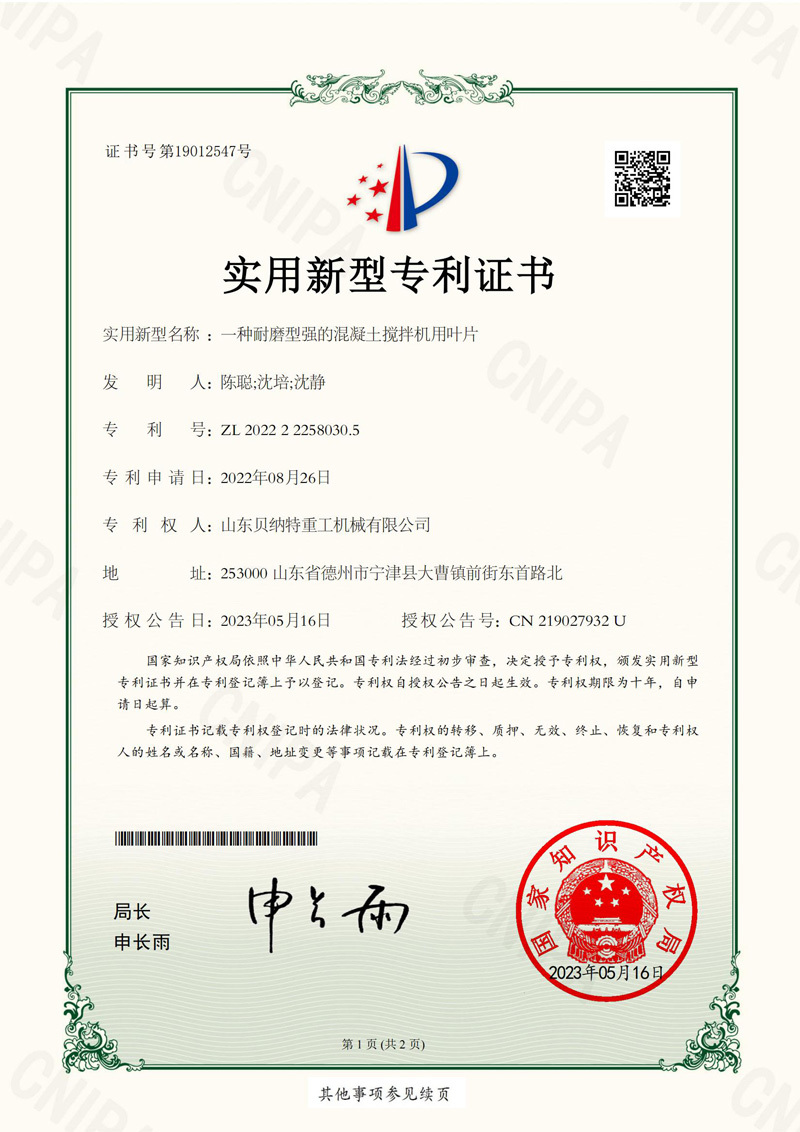

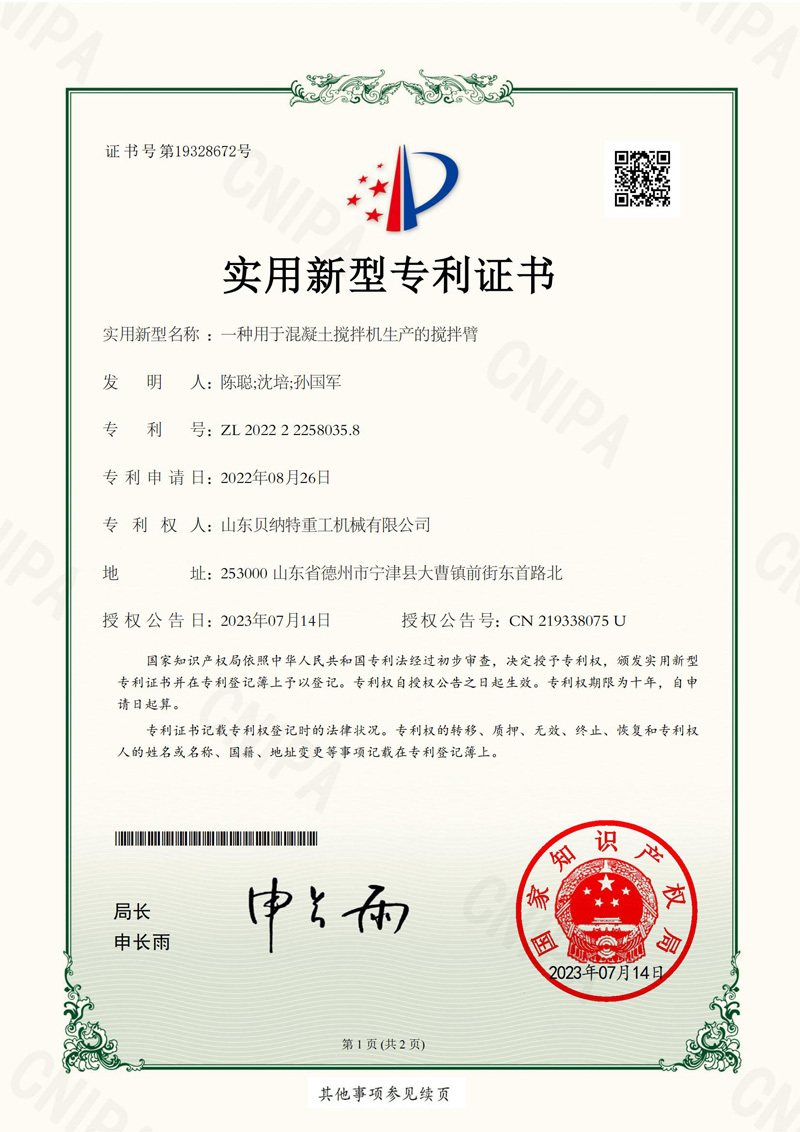

Quality Inspection Certificate

Casting production equipment

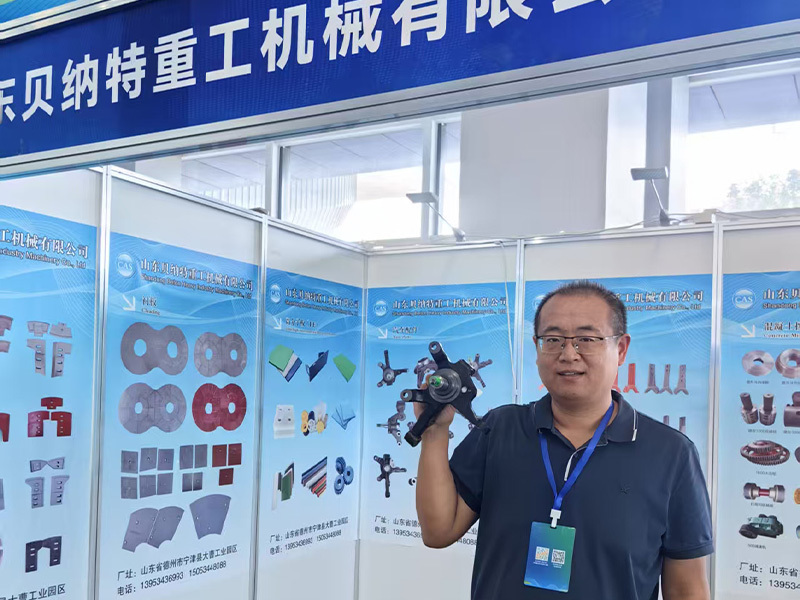

Exhibition

Inquiry

Please fill in the contact information and your needs, we will arrange professionals to contact you!

FAQ

Q

What types of mixer accessories does your company mainly produce?

A

We focus on producing the core wear-resistant parts of the JS series forced concrete mixers, including:

Mixing arm (double spiral belt/spiral blade type)

High chromium alloy liner (bottom plate/side plate)

Hydraulic seal shaft end assembly (including floating oil seal)

Wear-resistant alloy blades (spiral angle can be customized)

Wear-resistant guard plate for mixing tank

Q

How to ensure the wear resistance of the accessory material?

A

Triple strengthening process is adopted:

① Material upgrade: Liner/blade uses Cr20Mo2 high chromium alloy with a hardness of HRC58-62; shaft end uses QT600 ductile iron

② Structural optimization: The hyperbolic design of the mixing arm reduces material impact loss

③ Process guarantee: EPC lost foam casting

Q

How to confirm that the accessories match my equipment model?

A

Please provide any of the following information, and we will provide free adaptation verification:

✓ Host brand and model (such as: Sany JS2000, Zoomlion JS3000)

✓ Original accessories part number

✓ Measurement of key dimensions

Q

Is there any non-standard customization service?

A

We support personalized needs.