Quality Certification

Always adhere to advanced casting technology

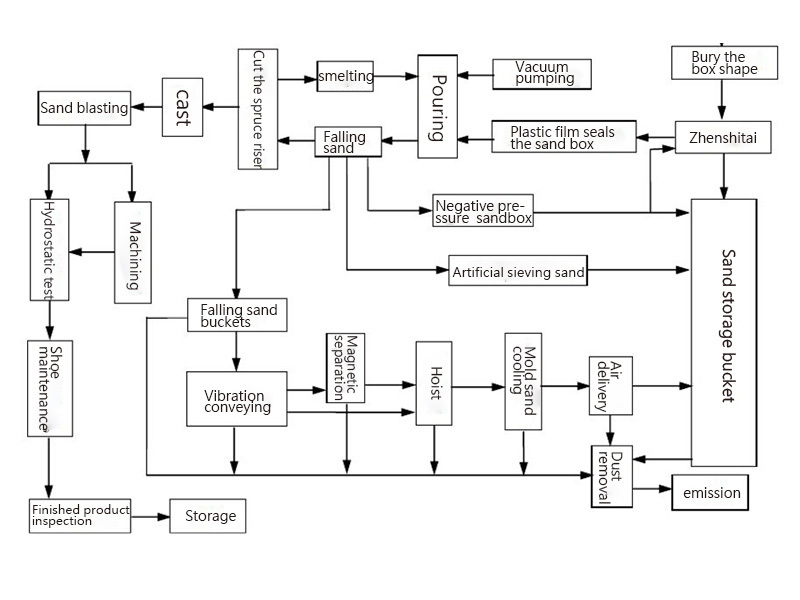

The company is the first company to introduce resin sand and water glass molding locally, and is also the first company to gradually phase out resin sand and water glass molding; the company adopts EPC casting technology and has an annual production capacity of 5,000 tons of castings. The unique vibration casting can effectively refine the grains and improve the wear resistance of the castings.Always adhere to strict molten iron out of the furnace temperature

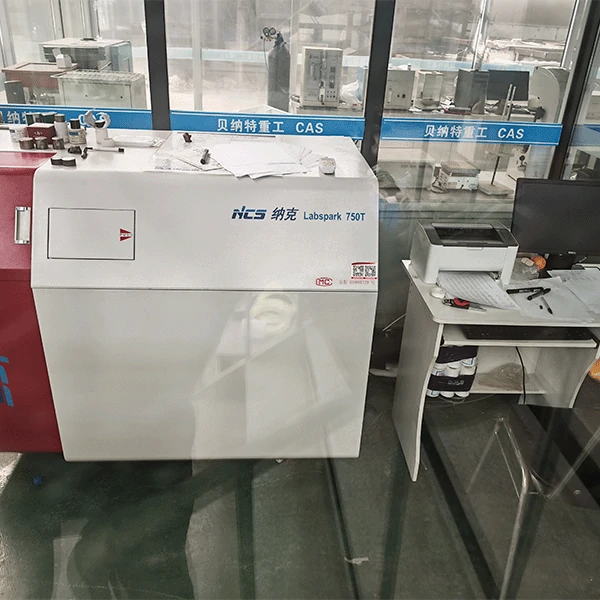

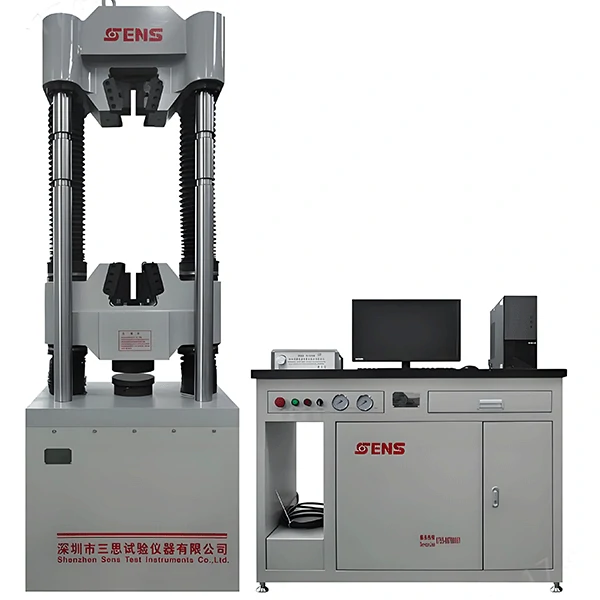

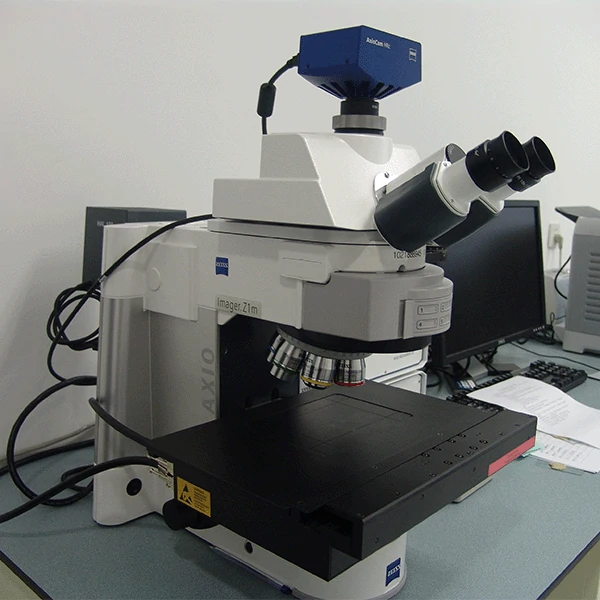

The same kind of molten iron but different furnace temperatures will produce different quality products. To achieve precise temperature control, the company has section chiefs at each process to conduct inspections and tests.Always adhere to advanced testing methods

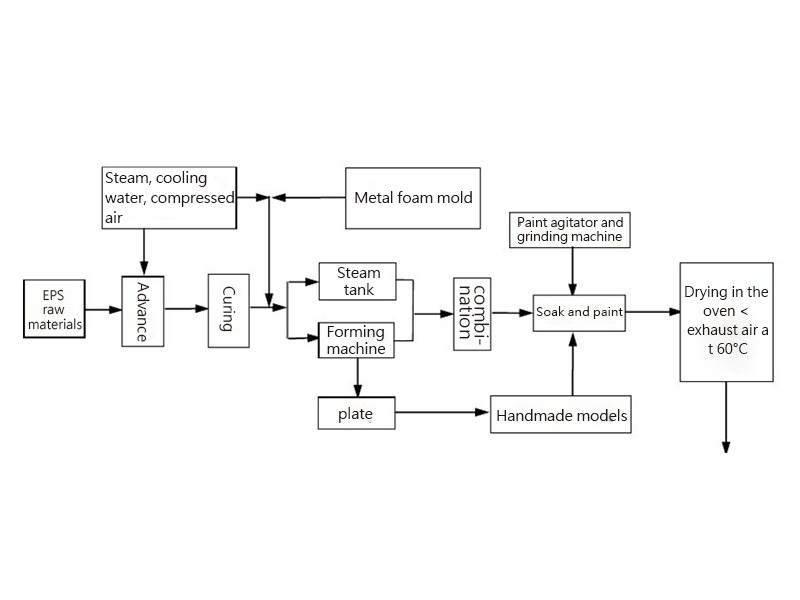

Always adhere to advanced testing methodsPhotos of the lost foam process

All castings are smelted in medium frequency induction furnaces, which can effectively ensure the purity of molten iron and solve the problem of material deviation. The chemical composition of castings can affect the quality stability of products. The company strictly controls the purchase of raw materials. According to long-term production practice and the material ratio promoted by the China Foundry Association, in addition to conventional elements, appropriate amounts of rare metals are added to ensure the wear resistance of the material. In order to quickly detect and adjust the chemical composition, the company has invested a lot of money in testing equipment to ensure the quality of the products.